CASE STUDY

Portable Ozone-Based Sterilization

P3PD supporting SteriO3’s Ross M1 design update to provide sterile surgical capability, anywhere on Earth

MEETING THE NEED FOR TRUE FIELD STERILIZATION

At Phase Three Product Development (P3PD), based in Colorado, we partner with innovators who need full-spectrum engineering services to bring complex ideas to market. When Dr. Steve Hughes, founder and CEO of SteriO3, came to us, he had one clear mission—to make sterile surgical capability available anywhere on Earth.

Traditional hospital sterilizers are large, power-hungry, and very difficult to transport. In field hospitals, humanitarian missions, and remote medical outposts, these systems simply don’t work. Dr. Hughes, a materials scientist with a background in orthopedic implants, recognized this critical gap in healthcare infrastructure and set out to build the ROSS M1, a rugged, portable sterilization system that could operate in low-resource environments.

Years earlier, Steve’s team won a U.S. Air Force grant to prototype a compact ozone-based sterilizer. When that early project ended, he acquired the technology himself, forming SteriO3 to finish what the prototype started. The company’s goal: a single-person-carry sterilizer weighing less than forty pounds, capable of full sterilization cycles in under an hour.

That’s when P3PD got involved.

THE CHALLENGE: SHRINKING A LAB SYSTEM

By the time we joined the project, SteriO3 had proof-of-concept data but faced significant engineering hurdles. The core chemistry, ozone combined with hydrogen peroxide, was sound and environmentally safer than ethylene oxide. The real challenge was one of product engineering and prototyping: compressing a full sterilization process into a small, durable, energy-efficient unit that could be deployed anywhere.

As Steve put it, “The hardest part wasn’t the science—it was making it work inside the box.”

He needed an engineering partner capable of taking a research-grade prototype and transforming it into a manufacturable, user-friendly product. That meant upgrading electronics, fluidics, and the user interface while maintaining safety, reliability, and performance under tight time and funding constraints.

“Phase Three brought every skill set we didn’t have in-house—electronics, software, mechanical design, and fluidics. They elevated our system from 2010 to 2025.”

— Dr. Steve Hughes, Founder & CEO, SteriO3

WHY P3PD WAS THE RIGHT PARTNER

Our connection began through the Innosphere Ventures Life Sciences Incubator program, where Steve and P3PD founder, Kris Buchanan, had met years earlier. When it came time to commercialize the ROSS M1, that existing trust and proximity made all the difference.

At P3PD, we believe product development is most effective when teams work closely, even side-by-side. Being located just up the road allowed for weekly, in-person collaboration and rapid design reviews, prototype iterations, and hands-on testing which were all more effective than video calls.

Equally important, we bring a full range of multidisciplinary engineering services under one roof: mechanical, electrical, firmware, software, and fluidics. For an early-stage company like SteriO3, outsourcing these capabilities provided instant scalability without the overhead of hiring a full internal team.

“I’m a hands-on engineer. Being able to drive up the road, test something, and tweak it together—that’s huge.”

— Dr. Steve Hughes, Founder & CEO, SteriO3

OUR APPROACH: FROM PROTOTYPE TO COMMERCIALIZATION

When we began working with SteriO3, our goal wasn’t just to fix isolated challenges, it was to help create a commercialization-ready platform. We started by analyzing the original Air Force prototype, identifying where modern engineering could deliver performance, safety, reliability, flexibility, and manufacturability improvements.

Our work centered around three key areas:

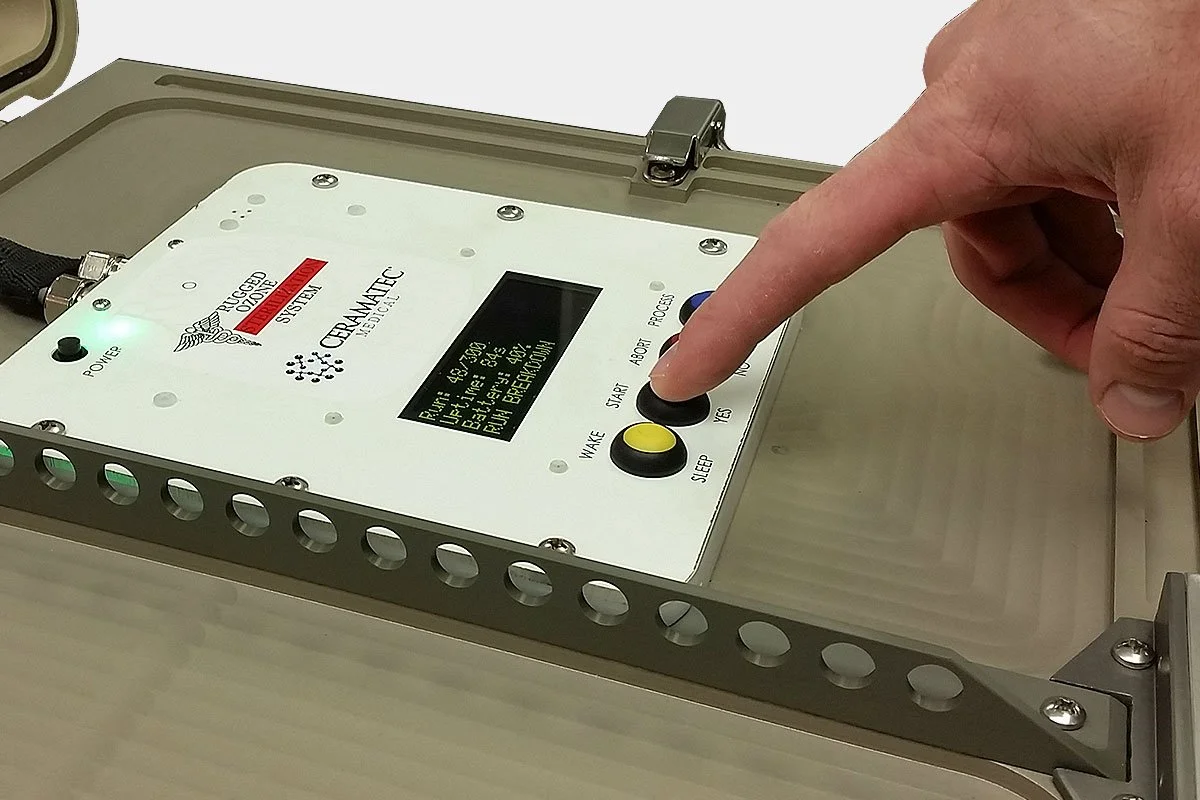

Electronics & Firmware Modernization: We critically examined and updated the control electronics from the ground up. This included designing new circuit boards, replacing legacy components, and writing firmware that automates test cycles, tracks performance data, and streamlines validation. The result is a smarter, more flexible sterilization system that accelerates product prototyping and testing.

Fluidics and Gas-Liquid Delivery Optimization: Because the ROSS M1 relies on both gaseous ozone and a fine mist of hydrogen peroxide, we applied our deep fluidics engineering expertise to ensure precise, consistent delivery. Our updates improved sterilant formation and distribution, reduced waste, and created a more robust subsystem for future manufacturability.

Human-Centered Design and User Interface: We reimagined the user interface for simplicity and reliability in high-stress environments. With intuitive controls and visual indicators, operators can run predefined sterilization cycles at the push of a button, which is ideal for field medics, veterinarians, or disaster-response teams.

Throughout the process, our engineers worked hand-in-hand with Steve and his team. Weekly meetings at our Colorado facility meant ideas moved directly from conversation to prototype quickly.

THE OUTCOME: A MODERN, READY-TO-VALIDATE DEVICE

Within months, our collaboration delivered a late-stage prototype with dramatically improved functionality, safety, and usability.

Automated Testing & Iteration: New firmware enables rapid cycle optimization and data collection.

Optimized Fluid Delivery: Consistent gas-liquid distribution supports repeatable sterilization performance.

Integrated Design: The re-engineered system provides a robust foundation for product commercialization and design-for-manufacture (DFM) activities now underway.

This wasn’t about cost reduction, it was about unlocking potential. With an agile, test-ready prototype, SteriO3 can now validate its chemistry, prepare regulatory submissions, and scale confidently.

WHAT’S NEXT FOR STERIO3

The ROSS M1 is entering its final development phase. In 2026, SteriO3 plans to begin FDA 510(k) submission and launch a Series A funding round to support manufacturing and commercialization.

The team will soon deploy beta units for veterinary field testing, a practical proving ground that mirrors the demands of humanitarian and military use but with a faster feedback loop. In parallel, they continue working with U.S. military programs to validate the system for field sterilization.

The long-term vision extends beyond the battlefield: SteriO3 aims to bring this clean, ozone-based sterilization technology into hospital reprocessing environments, offering a sustainable alternative to ethylene oxide systems that are being phased out globally.

A COLORADO PARTNERSHIP BUILT ON TRUST

For us at Phase Three Product Development, this project exemplifies what we do best—help visionary teams navigate the full journey from concept to prototype to commercialization.

We didn’t just deliver engineering drawings or CAD models; we became a seamless extension of the SteriO3 team. By combining our Colorado-based engineering services with their deep understanding of sterilization science, we accelerated development and helped them move toward a commercially viable, life-saving device.

“For startups like ours, outsourcing to a partner like Phase Three lets you move faster without the overhead of building a full internal team.”

— Dr. Steve Hughes, Founder & CEO, SteriO3

FROM INNOVATION TO IMPACT

At P3PD, we help clients transform great ideas into manufacturable realities. Whether it’s organ-on-chip systems, regenerative-medicine instruments, or now portable sterilization units, our team thrives on solving complex problems at the intersection of life-science innovation and product engineering.

The ROSS M1 is proof that with the right partner, you can take a bold idea and turn it into a product that changes what’s possible. One prototype, one iteration, and one collaboration at a time.

STARTING WITH YOUR INSPIRATION

Phase Three Product Development (P3PD) has simplified the product development process in the life science and medical device industries.

Arthur’s Rock - Fort Collins